High-Purity Tank and Vessel Valves & Accessories

Features:

- Hygienic, aseptic, ultra-sanitary designs

- Total packages with mix tanks and vessels

- Lightweight polymer construction

- USP VI and FDA certificates available

- White Mountain Process high-performance design

White Mountain Process supplies a range of high-purity valves and fittings and custom poly fabrications included with our high-purity mix-tank, vessel and storage-tank packages.

We offer complete tank and vessel packages of carefully selected components, engineered and documented to meet the hygienic, aseptic and ultra-sanitary needs of the medical, pharmaceuticals, biopharmaceuticals and electronics industries. This includes all FDA, cGMP and USP VI requirements with proper material certifications and traceability.

Designs and materials are also available for less-demanding food, chemical and electronics production applications and for industrial blending system applications.

Available in a range of polymers and plastics, our high-purity valves present a number of advantages over stainless steel valves, including:

- No corrosion

- Lower cost

- Lighter weight

- Typically, negligible leaching (per multiple leachables/extractables studies.)

- Higher chemical resistance

- No thread seizing to metal

For more-detailed information on high-purity tanks and valves, please see our white paper.

See our concept drawing of a White Mountain Process mix-tank with accessories (PDF)

Valve Types

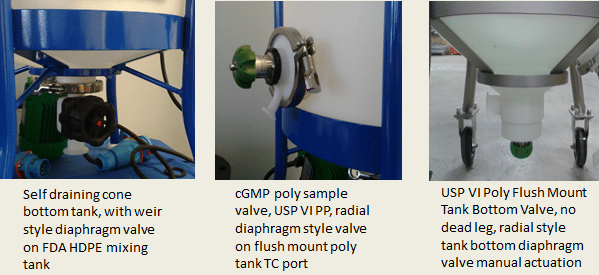

White Mountain Process offers sample valves and tank-bottom valves in three designs:

- Radial diaphragm valve flush-mount, no deadleg (aseptic, hygienic, ultra-sanitary)

- Weir diaphragm valve (weir style similar to Gemu®, ITT®, Saunders®)

- Ball valve

White Mountain Process is one of the very few companies able to supply ultra-high purity, hygienic, aseptic USP VI radial diaphragm flush-mount tank-bottom valves. Offered in USP VI PP, FDA PE, and USP VI PVDF, these no-deadleg valves are fully draining and are currently meeting the most demanding requirements at facilities around the world.

Inline valves are available for tank or vessel CIP piping and recirculation loops. These are offered in two designs:

- Weir diaphragm

- Ball

Design Details

Actuation: Manual and air-actuated (limit switch/position indicator is optional with automated valves)

Connection: Tri-clamp®

Sizes: ½” – 4”

Maximum temperature: Typical PE= 140 F and PP= 220 F and PVDF= 230 F

Maximum pressure: Most poly tanks are atmospheric design, so for any nitrogen blanket or pressure applications please consult www.wmprocess.com

CIP/SIP: All are CIP designs. SIP available, see further below.

Valve Materials

Valve bodies are available in FDA polyethylene (PE), Kynar® polyvinylidene fluoride (PVDF) or USP VI polypropylene (PP).

Diaphragm material options:

- USP VI PP

- EPDM

- Silicone

- Viton® fluoroelastomer

- Teflon® (PTFE)

SIP/Autoclavable Valves

Valves composed of PVDF and/or PP may be sterilized in place (SIP). Autoclavable designs are readily available; please inquire. Many of our mix tanks are fitted with autoclave-style top-entry agitators. For more information, please see our autoclavable mixer offerings.

Documentation Packages

- FDA certificates for PE valve materials

- USP VI certificates for PP and PVDF materials

Poly Plastic Sample Valve

- Non Metallic Biopharma ready sample valve

- USP VI Polypropylene with USP VI EPDM oring (other elastomers available)

- 1″ TC Standard, others optional

P/N WMP-SV-1.0″TC-USPVI-PP/EPDM

$584 USD + shipping Accessories

Contact us for other USP VI poly custom fabrications such as mixer impellers, autoclave agitators, USP VI dip tubes, spray nozzles, spray balls, spargers, manifolds, plastic fabrications, non-metallic mixing impellers, shaft assemblies and more.

For more-detailed information on high-purity tanks and valves, please see our white paper.

See our concept drawing of a White Mountain Process mix-tank with accessories

Contact us for a consultation or quote today. We love creating solutions!