Applications for Magnetically Driven Mixers

-

Biotech and Pharmaceutical Processing

-

Sterile Food and Beverage Production

-

Cosmetic and Personal Care Manufacturing

-

High-Purity Chemical Processing

-

Aseptic Formulation and Storage

Engineered for precision, purity, and performance in critical mixing environments.

White Mountain Process offers high-performance magnetically driven mixers for biopharmaceutical, food, and clean industrial applications where aseptic design and leak-proof operation are essential. Our mag drive mixers feature a bottom-mounted, magnetically coupled impeller system, eliminating the need for mechanical seals and ensuring 100% containment with zero particle shedding.

100% Containment: The magnetic coupling between the mixing head and drive unit ensures total integrity of the tank, preventing contamination and maintaining sterility.

Bottom Entry Design: The unique mixing head design and the position of the blades close to the bottom of the tank allow the mixer to run while the tank is being emptied, ensuring full product recovery and uncompromised cleanability.

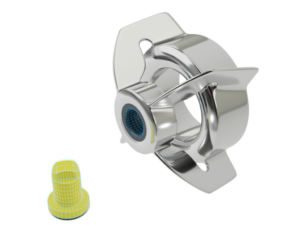

Zero Particle Shedding: The robust bearing combination of Zirconium Oxide (ZrO₂) and Silicon Carbide (SiC), along with fine-tuned geometry, ensures no particle generation, maintaining the integrity of the mixed media.

Aseptic Construction: All components are crafted from 316L stainless steel (Ra ≤ 0.5 μm) or exotic alloys to meet the strictest cleanroom standards.

Integrated Speed Sensor: Equipped with an intelligent speed sensor system, the mixer can detect the speed, position, and direction of the mixing head, providing reliable process control and validation.

Robust and Hygienic Design: The mixer head is machined from solid stainless steel (1.4435/316L), with a surface finish of Ra ≤0.5 μm, ensuring easy cleaning and compliance with hygienic standards.

Quick Maintenance: The drive unit is equipped with the patented Kest-Lock connection, ensuring quick disconnection from the tank plate during maintenance, minimizing downtime.

Biotech and Pharmaceutical Processing

Sterile Food and Beverage Production

Cosmetic and Personal Care Manufacturing

High-Purity Chemical Processing

Aseptic Formulation and Storage

Mixing Volume: Up to 22,000 liters

Design Temperature: 32°F to 302°F

Operating Temperature: 32°F to 275°F

Design Pressure: -14.5 to 145 psi

pH Range: 1 to 14

Surface Finish: Ra ≤0.5 μm

Compliance: Heat Certificate 3.1 acc. to EN 10 204

WMP has been providing “mixing solutions” to industry professionals for more than two decades.

We offer a large assortment of agitator, motor, and mount types – contact us today to request a quote.

Discover the benefits of world-class engineering and our White Mountain Peak-performance Team. We’re committed to making your job easier. Ask about our proprietary squeal-less dry-running mechanical seal for controlled-humidity environments. It’s blissfully quiet in performance!