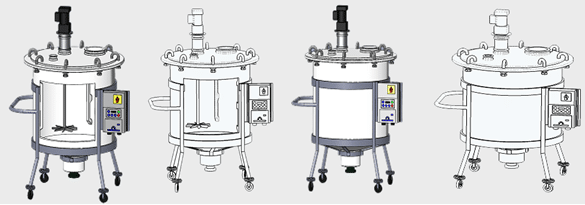

We offer a variety of open top, hinged lid top and sealed vapor tight mix tank setups depending on your application requirements.

We typically offer 4 categories of blending vessels depending on your needs:

- Industrial duty (typically FDA PE polyethylene process vessel for general blending of fluids and solids into liquids)

- Sanitary duty (PE and PP sanitary agitated vessels. Typical for food blending, beverage, dairy, cosmetic mixing)

- Corrosion Resistant (non-metallic mixers and agitated mix tanks with a variety of materials available including PE, PP, PVDF, PTFE, exotic alloys such as titanium and Hast C, cGMP, and USP VI poly materials readily available)

- Biopharma duty (USP VI cGMP process vessel with agitator 15Ra and electropolished 316Lss wetted parts, material certs, doc package, USP VI on any elastomers, typical for buffer prep, media make-up, vaccines, bioreactors, filter hold agitated vessels, chromatography makeup)

Typical applications for WMProcess high purity poly mixing tank systems:

- buffer prep

- media make-up

- vaccines

- bioreactors

- filter hold agitated vessels

- chromatography slurry media makeup

- pH adjust

- Diagnostic and reagent manufacturing

- Semi conductor chemical mixing

- Disposable mixing technology

- GMP biopharma blending

MIXTANK SIZES AVAILABLE = 1liter – 5,000gallons

Standard pre-engineered mixtank package prices are available – for more custom sanitary or biopharma duty mixtanks please contact WMProcess. Please note we offer premier sanitary and industrial duty engineered mixtanks, these are not typical junky tank/mixer packages you can find online or in catalogs.