Stainless Steel Mix Tanks – Systems

1 Liter – 10,000 Gallon Stainless Mix Tank Systems

White Mountain Process custom manufacturers stainless mix tank systems to your specifications. Please contact us for a quote to begin, we are a USA-based manufacturer and will respond quickly.

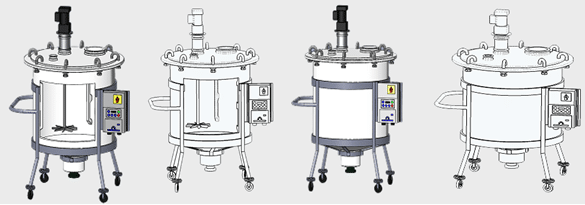

Our blending systems can be configured with stainless IBC tote tanks, open top circular process vessels, closed top pressure vessels, multi shaft, and multi-agitator mixers.

WMProcess will work closely with you to configure the optimum agitation package, from low shear cGMP blending to high shear mixing of difficult to blend high viscosity mixtures of gums and thickeners. Lab to production units in industrial duty and sanitary cGMP aseptic configurations are available. WMProcess offers top entry mixers, bottom entry sealed, magdrive mixers and side entry agitators.

We offer a variety of open top, hinged lid top and sealed pressure rated mix tank setups depending on your application requirements.

We typically offer 3 categories of blending vessels depending on your needs:

- Industrial duty (typically mill finish 304ss wetted parts for general blending of fluids and solids into liquids)

- Sanitary duty (32Ra or #4 sanitary polished tank ID and mixer wetted parts, 304ss and 316Lss most common. Typical for food blending, beverage, diary, cosmetic mixing)

- Biopharma duty (15Ra and electropolished 316Lss wetted parts, material certs, doc package, USP VI on any elastomers, typical for buffer prep, media makup, vaccines, bioreactors, filter hold agitated vessels, chromatography makeup)

MIXTANK SIZES AVAILABLE = 1liter – 10,000gallons

Some standard pre-engineered mixtank package prices are shown above – for more custom sanitary or biopharma duty mixtanks please contact WMProcess. Please note we offer premier sanitary and industrial duty engineered mixtanks, these are not typical inadequate tank/mixer packages you can find online or in catalogs.

Other Helpful Links:

- Mix Tank Concept Drawing (PDF)