“Always use the right tool for the job.” “Take care of your tools and they will take care of you.” These classic words of wisdom certainly apply equally to manufacturing equipment. Mixing + Blending machinery mismatches and breakdowns cost you money due to downtime, scrapped poor quality batches, equipment repairs, and lost production. Optimized agitation equipment and perfected operating procedures bring successful mixtures and profits and a sense of satisfaction from a job well done. Mixers and agitators, are essential elements of complex processing systems, and should provide many years of valuable service if you avoid:

The 7 Deadly Sins of Improper Mixer Operation

The Underpowered Mixer

A wimpy mixer will get sand kicked in its face every day. Invest in a mixer you can be proud of! An undersized mixer typically will not provide enough flow, and enough agitation to successfully provide 100% uniformity in your tank. Other blending disasters from not enough flow and HP could result from solids settling at tank bottom, stratifications in tank, non-uniform heat transfer, ineffective mixing of viscous product, poor dispersion, and a host of other issues. This outcome is quite understandable, but then again, so is the desire to save money. You of course are in business to make money, not simply to try to save it. Spend some time consulting with mixing and blending experts like those at White Mountain Process. Any good agitator vendor should ask the right questions about your application, your tank, and your mixture. Your payoff will be a mixer with the muscle to thoroughly blend your ingredients in the shortest possible time. If the mixer lacks sufficient horsepower, it may not create the required flow in the vessel for proper mixing. SOLUTION– Mixer should be sized properly for the application, with enough HP and enough flow (mixing capability) to provide the proper uniformity in an acceptable time frame.

Improper Shear – “Too Much or too Little”

Shear stress is a force that acts on an object that is directed parallel to the object’s surface. Shear stress is imparted by the mechanical action of the mixer and is determined by factors such as the rpm of the mixer, tip speed, the impeller configuration, the clearance between the impeller and the mixing vessel, as well as the viscosity and rheology (change in viscosity vs. strain rate) of process fluids. Some fluids become less viscous (thinner) with increased shear strain rate and others become more viscous. The viscosity of a few other fluids, such as water, are unaffected by shear strain rate. Shear is a necessary condition in certain mixing applications, particularly in breaking apart particle agglomerations, creating emulsions, dispersions, particle size reduction, milling, and homogenizing. But as with many things, too much of a good thing can sometimes be a bad thing. Over-shearing sensitive particulate, mammalian cells, and shear sensitive solutions can destroy expensive batches of product. Low shear mixers are better suited here, with gear drive slow speed designs implementing low shear mixing impellers. Some process components–such as many minerals–are insensitive to high shear, while others–such as biomolecules–may be degraded under such conditions. Some materials may vary in sensitivity depending on factors such as temperature or pH. Be sure that you understand the shear requirements and sensitivities in your mixing application. It may be necessary to conduct experiments to determine optimal conditions of shear and the length of time the materials are subjected to that shear. SOLUTION – size the mixer to the proper low, medium, or high shear ranges required to achieve process results. Low shear mixers are typically slow speed, and high shear mixers are high speed and employ various impellers or mixing heads to impart large shear forces.

Incompatible Materials of Construction

Mixer shafts and blades are commonly produced from various grades of stainless steel (SS) for high strength and corrosion resistance. But stainless steel can corrode, causing pits that may form cracks, which in turn may lead to mechanical failure of the part. The corrosion resistance of SS is imparted by the addition of chrome at a level of at least 10.5%. Nickel is also often added. The chrome forms an extremely thin barrier layer of chromium oxide on the surface, which protects against corrosion such as common rust. However, the barrier layer may be degraded by chlorine (a component of table salt), fluorine, iodine, and certain fatty acids. Type 316 SS contains 2% molybdenum, making it considerably more resistant to solutions of sulfuric acid, chlorides, bromides, iodides and fatty acids at high temperature than the 304 SS alloys. In the production of certain pharmaceuticals, SS grades containing molybdenum are required in order to reduce metallic contamination. It is important to note that 316 SS, although more corrosion resistant than the 304 alloys, may not be sufficient for some conditions. Various specialty metals and polymers offer a higher level of corrosion resistance than SS alloys. These include: a) Hastelloy® C22 and C276 b) Titanium c) AX6LN d) Polymers such as Teflon® PTFE, Halar® ECTFE, Kynar® PVDF, rubber, PVC, polyethylene (PE), and polypropylene (PP) Highly abrasive process materials may erode the electro-polished finish on metal parts, degrade the barrier layer on SS, and cause pits that are difficult to thoroughly clean. SOLUTION – Mixer Agitator materials of construction should be specified to handle the application, temperatures, abrasiveness, cleanliness, and acceptable materials if mixing pharmaceuticals. Special polishing, passivation, electropolishing, or coatings (Teflon, Kynar, Polypro) should be specified for mixer shaft and impeller assemblies and if any material certs, FDA or USP VI documentation is required that should be noted.

Insufficient Cleanability – Dirty Mixers are Bad News

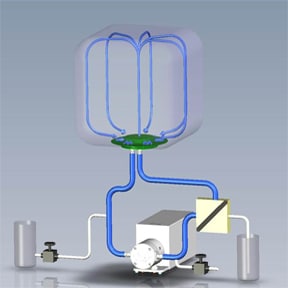

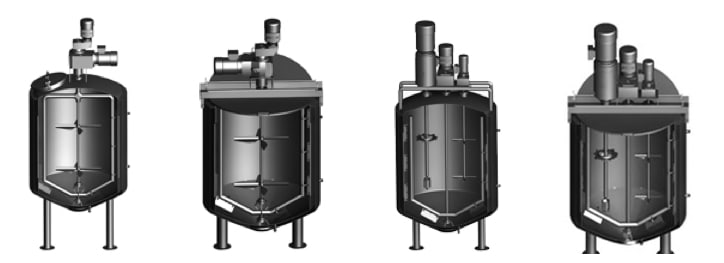

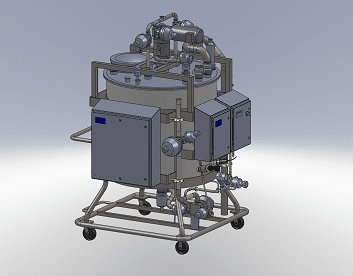

There is substantial diversity in mixer designs and materials, and a wide range in the ability of these mixers to be cleaned and sterilized. Add to this the variability in cleanliness required by the array of industries and processes in which mixers are used, and it becomes apparent that this factor must not be the subject of guesswork. Insufficient cleanability must be avoided at all costs, whereas it may make little sense to spend money on designs far exceeding the process requirements. Parameters affecting cleanability include corrosion and erosion resistance of the mixer component materials, as well as equipment design parameters including crevices and the ability of parts to be disassembled and removed. For efficiency, some mixing systems are constructed so that they may be cleaned in place (CIP) or sterilized in place (SIP). This means that the unit does not require disassembly for cleaning or sterilization. For CIP/SIP, special spray-cleaning equipment is designed to clean all areas, and all materials are able to withstand the heat of sterilization. Metals of course will withstand sterilization temperatures, whereas certain polymers may not. Kynar® PVDF and polypropylene are two polymers that can stand up to many heat-sterilization processes. Another important consideration in cleanability is the type of connector or seal used at the point where the mixer shaft penetrates the vessel wall. Sanitary connectors such as Tri-clamp® (TC), NovAseptic® (NA),and TerraportTM allow optimum drainage of process materials and are fully cleanable. Sanitary mechanical seals offer similar advantages. For CIP, should the impeller be submerged in fluid? Do you want to CIP the mechanical seal debris well? Is the impeller set screwed to shaft, or welded/polished/electro-polished? SOLUTION – If a mixtank will be CIP and/or SIP proper good design practices should be implemented for the agitator. The mixtank design is crucial for good cleaning, and properly specified spray balls/nozzles to accommodate full coverage and complete cleaning of tank/mixer/accessories.

Unsuitable Documentation Package

“In God we trust. All others bring data.” Your supplier may have told you that you purchased a mixer meeting the requirements of FDA, USP, and other regulatory or standards bodies; your mixer may in all aspects of its design and manufacture meet those requirements. But if you do not have the proper documentation to back up that claim, then your mixer does not in fact meet the requirements. In order to ensure that sanitary mixers are designed and manufactured to stringent quality standards, including materials of composition, relevant oversight bodies have stipulated various specifications and documentation requirements. Among these are: Food & Drug Administration (FDA)

- Certificate of Conformity

- A Certificate of Conformity offers little data, and usually just says the product or material meets the purchaser’s specifications or those of some standard.

- Certificate of Analysis

- A Certificate of Analysis provides data, including the specifications of the product or a confirmation that they fall within a certain range. A Certificate of Analysis also normally provides information about known deviations or contaminants. The FDA normally prefers Certificates of Analysis over Certificates of Conformity.

- Current Good Manufacturing Practices (cGMP)

- The FDA requires that equipment used in pharmaceuticals production be manufactured in facilities meeting cGMP standards, and the purchaser of high-purity mixing equipment may require that the supplier provide a copy of its FDA cGMP manufacturing facility certification.

U.S. Pharmacopeia (USP)

- USP VI

- The USP defines six plastics classes, from I to VI, with VI the strictest. Plastics manufacturers may have their plastic resins certified as USP Class VI. A plastic resin material that has passed Class VI certification is expected to be biocompatible.

- The USP Class VI conforming equipment must be made from materials with clear histories of biocompatibility that meet tight requirements for leachates.

American Society for Testing & Materials (ASTM)

This is a test report used for metals that certifies that the metal material meets certain standards set by organizations such as the ASTM, ASME, or ANSI, etc. SOLUTION – Any documentation required for mixer materials of construction, motor/gearbox, mechanical seal, etc., should be specified with your mixer inquiry to assure complete compliance with the final turnover package. Mixing Vessel is Not Suitable A mixer is part of an interdependent system including the vessel or tank into which the mixer is inserted. Parameters of the vessel that affect mixing efficiency and effectiveness include:

- The presence and placement of baffles to direct the process fluid toward the mixer impeller(s)

- The position of the mixer in the vessel: top, bottom, or side mounting. Bottom-mounted mixers offer greater efficiency than top- or side-mounted designs.

- Number, location, and design of the mixer impeller(s)

- The presence and effectiveness of a vortex breaker

- The design and location of the vessel outlet valve

- The presence and design of a recirculation loop

- Single- or multi-shaft mixing

- Open or closed vessel and temperature/pressure rating

- Material of construction, such as SS or poly

- Sanitary connectors for all connected pipes and equipment if necessary

- The ability of the system to be CIP/SIP

SOLUTION – Mixing tank geometry, features, and design are as crucial to mixing performance as the HP and speed of the actual agitator. Careful attention to process vessel design to meet all your needs (mixing, cleaning, instrumentation, self-draining, heat transfer…) will help make the mixer perform as expected.

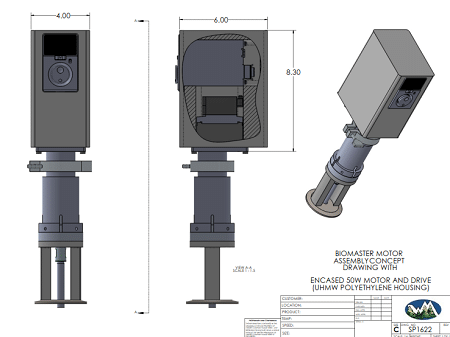

Mixer Options are Not Dialed-in

There are a number of options in mixers. Be sure to thoroughly evaluate those available or seek expert advice regarding your application. Some of these are:

- Variable speed and its range

- Tachometer to monitor actual mixer shaft speed

- Mechanical seals for sanitary applications

- Special finishes

- Low level mixing

- Multiple or customer impellers

- Split mixer shaft

SOLUTION – Carefully choose the options required with keeping financial impact within your range.

AVOID the 7 Deadly Sins of Improper Mixer Operation

Stay away from high risk and painful experiences. Take the time to get expert assistance, and purchase the correct high-quality mixing system to make your next mixer installation a good one. We at White Mountain Process assume that is your goal, and we know it is ours. A properly selected mixer, sized for your tank and process conditions, when further combined with a flawless installation, delivers a happy day for all of us. Some good reference documents: Mixer buyers guide Mixer data sheet Mixtank concept drawing Contact White Mountain Process for an engineering consultation; we love creating solutions!