When it comes to industrial mix tanks, the material you choose can significantly impact the success and efficiency of your processes. Stainless steel is popular for its durability, corrosion resistance, and hygienic properties.

Achieving optimal chromatography media slurry mixing isn't just about having the right equipment; it's about understanding the process and employing the best practices.

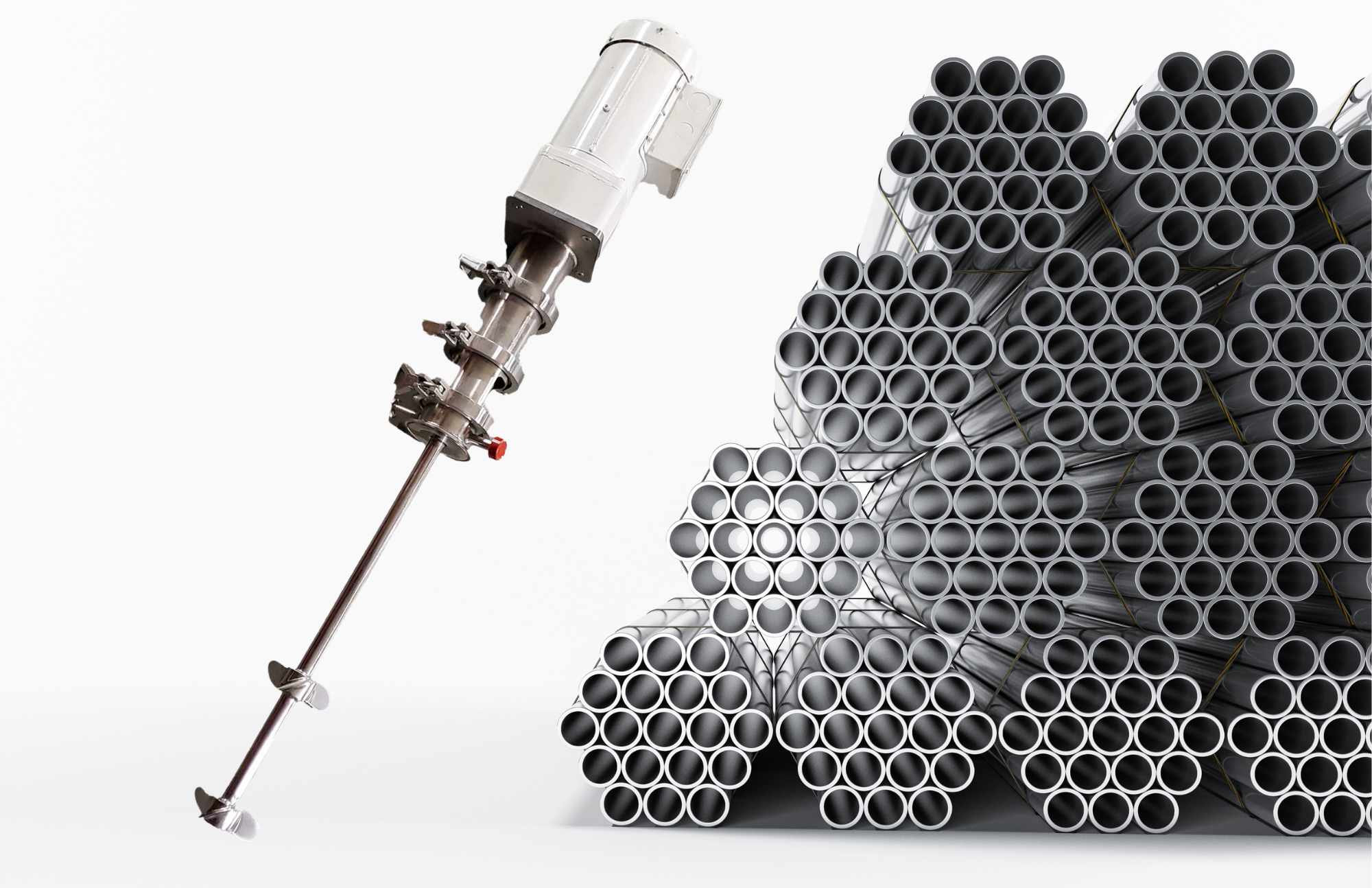

Choosing between impellers and propellers for your bioprocess system depends largely on the size of your tank and the viscosity of the material you are processing.

The addition of tank baffles to your sanitary mixing system might seem like a minor detail, but their impact is significant.

White Mountain Process, an esteemed global leader in the provision of top-tier mixing and blending solutions and equipment for the biopharmaceutical industry, has officially announced its participation at networking the highly anticipated ISPE BOSTON products show.

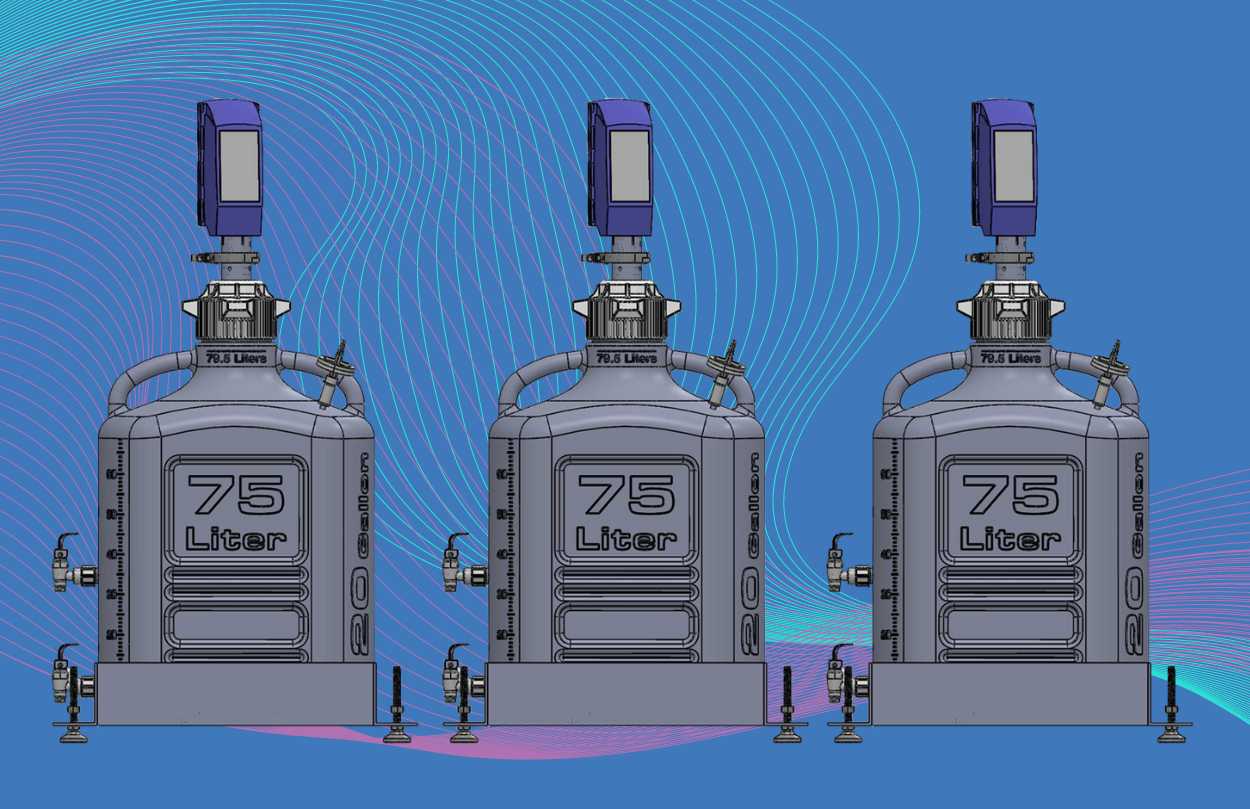

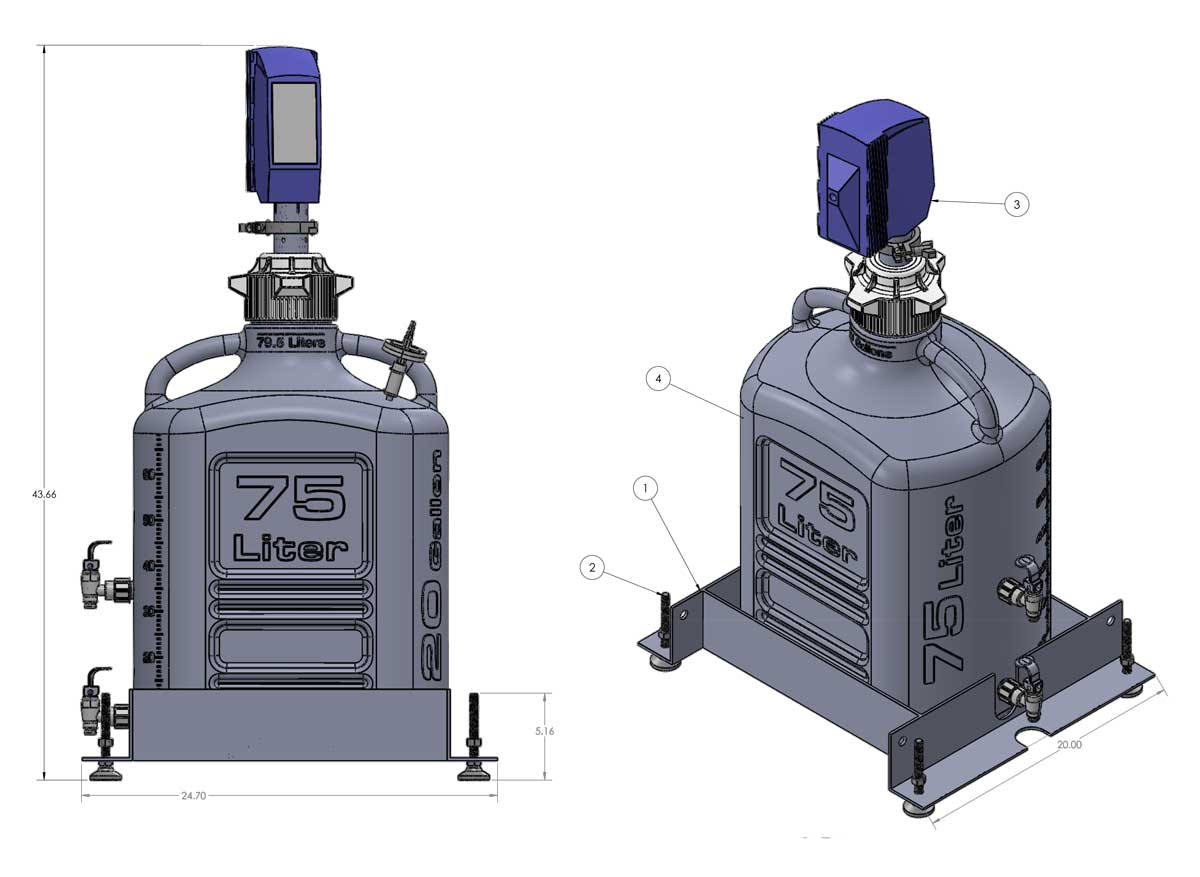

Different carboy mixers have diverse mixing abilities, which makes choosing the right one crucial. Direct drive mixers are ideal for light-duty low-viscosity mixing, while gear drive mixers are suited for heavy-duty mixing like resin slurry suspensions.

WMProcess.com's sanitary mixing solutions are efficient at small volumes and easily scalable for high-volume production. This adaptability allows biotech manufacturers to increase production capacity without compromising blending quality.

In the rapidly advancing field of biotech, efficient and reliable mixing and blending processes are essential for ensuring high-quality products and maintaining regulatory compliance.

Sanitary plastic mixing tanks tanks offer numerous advantages over traditional alternatives, making them a preferred choice for biotech manufacturing facilities.

Buffer preparation is a critical step in many laboratory, biotech, and pharmaceutical GMP blending processes.