The Benefits of Bottom Entry Mixers

Kwilliams Bottom Entry Mixers, Biopharmaceutical Use, Industrial Use, Sanitary Mixers

The Benefits of Bottom Entry Mixers over Top Entry Mixers from White Mountain Process

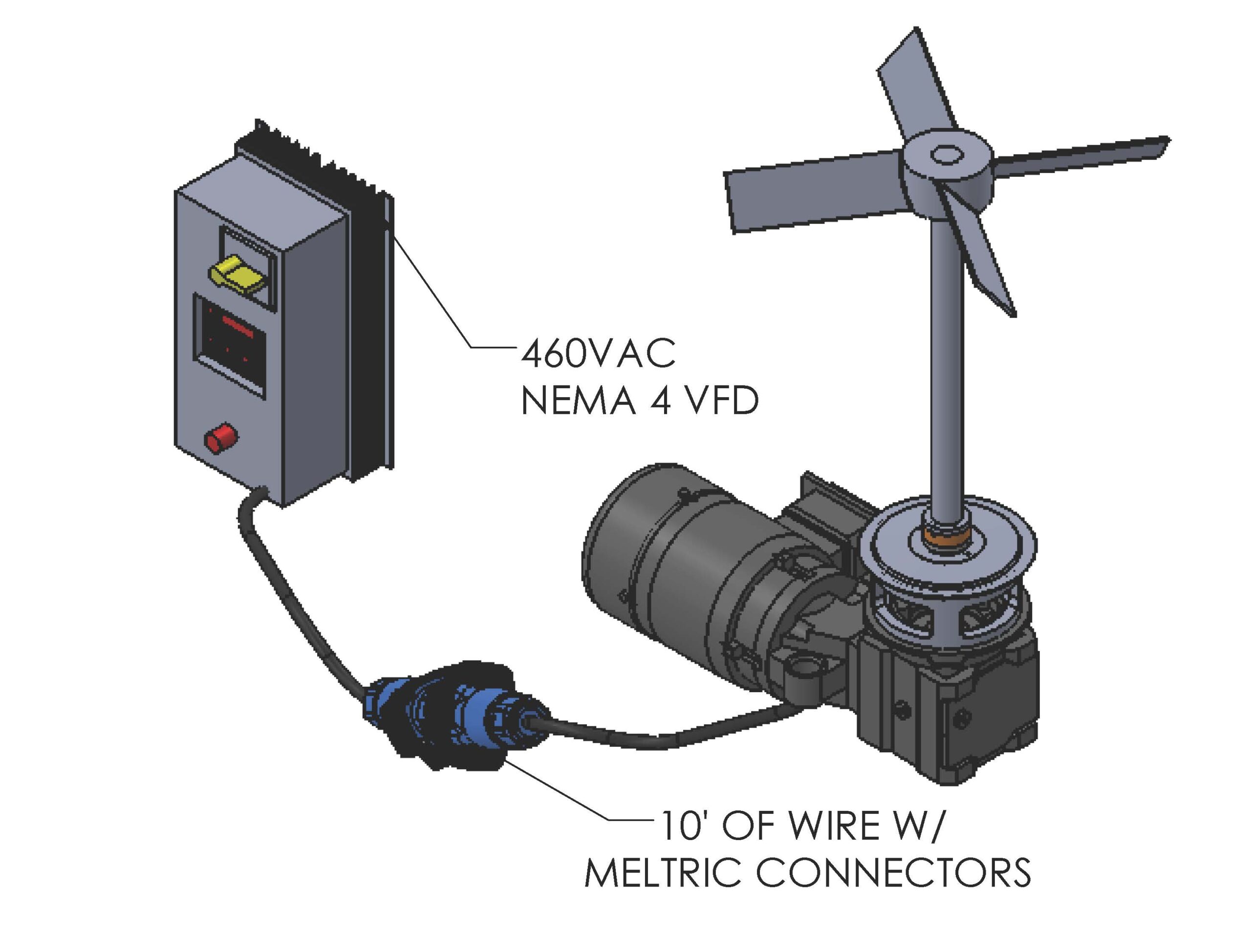

Southbridge, MA – White Mountain Process offers Bottom Entry Mixers that are ideally suited to mixing and blending applications in the pharmaceutical and beverage industries. The company offers standard mixers and agitators, which are bottom mounted to the tank via weld pad, ANSI flange, or TC tri clamp sanitary connection. Mixers are available in high flow/low shear blending designs, or bottom agitators are also available for high speed and high shear dissolving.

The benefits of Bottom Entry Mixers:

- Low level mixing. The ability to mix to very low levels, and blend during drawdown and tank pump out.

- Ease of installation. Very easy to install and simple to maintain the mixer drive/gearbox since it is at the bottom of the tank.

- More efficient mixing. The design of a bottom entry mixer promotes uniform mixing of the batch that continues until the vessel is almost completely drained.

- More available headroom. Top entry mixers can take up valuable room on the tank top. Bottom mount mixing design eliminates that issue.

- Easier access for maintenance. Their low entry point makes them more accessible for maintenance. This also reduces safety concerns, which are always an issue when dismantling top entry mixers for maintenance and repair.

- More efficient cleaning-in-place (CIP). Mixer design enables more efficient CIP than the cleaning process of the agitator and shaft associated with a top entry mixer.

- Bottom Entry Magnetic Drive Mixers are ideal for sanitary applications. The bottom mount sanitary magnetic mixer is a standard for sealless mixing and the elimination of a mechanical seal. A drive unit connected to the bottom of the tank is fitted with a magnet. When the drive turns, it locks onto a magnet on the mixer impeller to make it turn. The impeller is mounted on a spindle that is welded to a mounting plate inside the tank. Because there is no breach of the tank wall in this design, there is no need for a seal and sterility is almost guaranteed.

Applications for the Use of Bottom Entry Mixers:

- Buffer prep and Media prep

- Dissolving of solids such as salts

- Blending and dissolving difficult- to- wet powders and gums into liquids

- Low shear and high shear applications

- Filtration product hold tanks

- Yeast propagation

- Chromatography slurry

For more information view https://wmprocess.com/bottom-entry-mixer/

Mike Matton

About White Mountain Process

White Mountain Process is a USA based company that supplies sanitary mixing and blending equipment throughout the world. The company prides itself in offering real, experienced help to solve elaborate mixing problems with a goal of optimizing your blending process. We offer extensive engineering support and application assistance for any mixer, agitator, mechanical seal, mixing tank, or complex automated blending system.