7 Mix Tank & Mixer Calculators That Can Help You Streamline Your Purchase Process

Mixing and Mix Tank Calculators

White Mountain Process is happy to provide these free mixing calculators. We hope our calculators help you decide on preliminary mixer sizing, mix tank volume calculations, mechanical design calculations, etc. The mixer selection program allows you to calculate flow rates and power draw of mixing impellers, see what the agitator will provide for tip speed and tank turnovers per minute, and estimate tank mixer sizings.

NOTE: these are for REF ONLY. For confirmation on mixer selections or agitator design, don’t hesitate to get in touch with us at sales@wmprocess.com. We will be happy to assist.

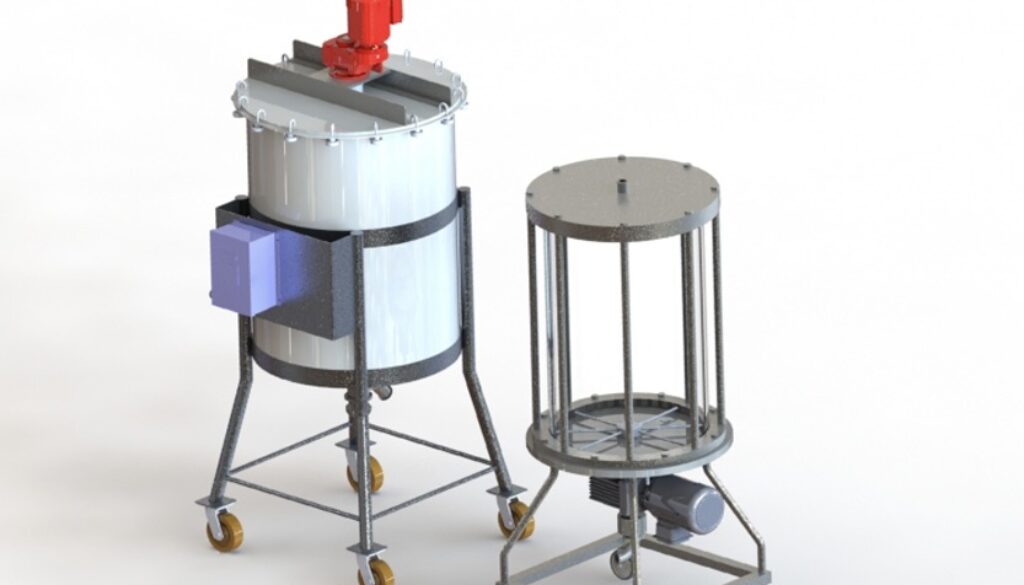

White Mountain Process designs and builds sanitary mixers, mixing tanks, and blending systems for the biotech, pharmaceutical, cosmetic, food and beverage, sanitary and industrial processors who need precise mixing and blending to assure quality end products and process results.

We do offer free consultations. Please email us anytime.

TANK VOLUME CALCULATOR

Calculate tank volume by choosing the appropriate vessel diameter, straight side height, the liquid level in the tank, and the shape of the bottom (different bottom head geometries can provide different mixing results). You should always maintain 20% or so headroom/vapor space for cleaning spray nozzles etc.

TANK WEIGHT CALCULATOR

Excellent to calculate the weight of tanks and vessels does not include the weight of mixer so contact us for details of that

MIXER TORQUE & AGITATOR BENDING MOMENT CALCULATOR

Part of typical mixer design calculations used for sizing mixer shaft, confirming mixer speed range, etc

CRITICAL SPEED CALCULATOR

Part of typical mixer design calculations used for sizing mixer shaft, confirming mixer speed range, any lockout speed due to critical speed of mixer shaft, etc

CONVERSION CALCULATOR

The unit conversion calculator is always helpful

MIXING TANK JACKET – HEATING & COOLING

Heating and cooling mixing tanks is a crucial process. Typically, you want 100% mixing uniformity and temperature profile homogeneity in the mixing vessel. This is a guide only, and you usually will pump approx.. 10gpm through a mixing jacket. Note: Precise calculations should be made by an authorized HVAC person to confirm which heating/cooling media, flow, temp, fluid, etc will work best with the tank jacket.

MIXER SELECTION CALCULATOR

Helps choose mixer design based on many variables, including HP, Speed, Mixing impellers and # of impellers, and desired turnovers per minute (i.e., two turnovers/min are great for pH adjustment of waterlike fluids, and ten turnovers/min are the target for complex mixing application such as chromatography resin slurry blending (resin slurry makeup in a mix tank).