5 Ways to Optimize Your Bioprocess Results with Carboy Mixers

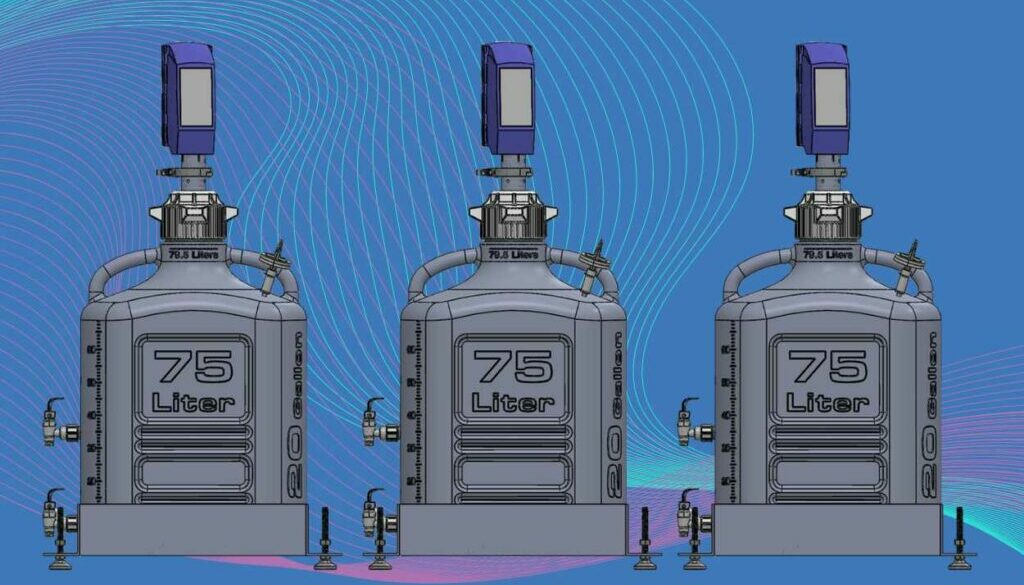

At White Mountain Process (WMProcess), we understand that bioprocess optimization is at the forefront of achieving excellence in any biotechnological endeavor. One such way to ensure streamlined processes is by utilizing carboy mixers. These mixers play a crucial role in making processes like buffer prep, media prep, reagent and diagnostic blending, and product storage more efficient. Here are five ways to optimize your bioprocess results using carboy mixers:

1. Choose the Right Mixer for Your Needs

Different carboy mixers have diverse mixing abilities, which makes choosing the right one crucial. Direct drive mixers are ideal for light-duty low-viscosity mixing, while gear drive mixers are suited for heavy-duty mixing like resin slurry suspensions. By using the correct type of mixer, you can optimize your bioprocess by ensuring efficient mixing and preventing equipment damage, thereby saving time and resources. A variety of air and electric motors are also available to choose from.

2. Leverage the Benefits of Single-Use Systems

Consider using single-use carboy mixers to enhance productivity and reduce contamination risks by COP cleaning. Single-use systems are excellent for bioprocesses as they eliminate the need for cleaning and sterilizing, reducing turnaround time and increasing productivity. With single-use carboy mixers, you can also avoid cross-contamination, ensuring a higher purity level for your bioprocess.

3. Maximize Mixing Efficiency

Enhancing your mixing efficiency is a simple yet effective way to optimize your bioprocess. The primary way to achieve this is by determining the optimal mixing speed for your process and choosing the right impeller for the mixing service. With WMProcess’s carboy mixers, you can easily adjust the RPM (rotations per minute) to find the most efficient mixing speed. Efficient mixing ensures homogeneity and facilitates better cell growth and productivity.

4. Optimize Mixer Performance

The positioning of your carboy mixer can significantly impact the efficiency of your bioprocess. The mixer should be positioned to create a vortex in the carboy if you are adding solids that float. Mixers should never be undersized; having the ability to adjust speed and control the degree of agitation allows full-volume turnover, ensures complete mixing, and gives the ability to turn the speed down during pump out. Carboys have one mixer port, center-mounted, so a rectangular mixer acts as a baffled tank, where a round carboy has more swirling affect.

5. Monitor and Control Process Parameters

Process monitoring and control are crucial to the success of any bioprocess. This includes maintaining optimal temperature, pH, and dissolved oxygen levels. WMProcess’s carboy mixers can be equipped with sensors to monitor and control these parameters continuously. By doing so, you can ensure your bioprocess is always in the optimal range, improving the consistency and quality of your results. Carboys which are available in USP VI PP and FDA HDPE materials can be fitted with sanitary welded fitting for valves, vent filters, dip tubes, etc., tri clamp and quick disconnect sanitary connection are all available.

To sum up, carboy mixers are an integral part of bioprocess optimization. You can significantly enhance your bioprocess results by choosing the right mixer, leveraging the benefits of single-use systems, maximizing mixing efficiency, optimizing mixer positioning, and monitoring and controlling process parameters. Remember, the key to success in any bioprocess is having the right tools and knowing how to use them effectively.

With carboy mixers, you are one step closer to achieving bioprocess excellence.